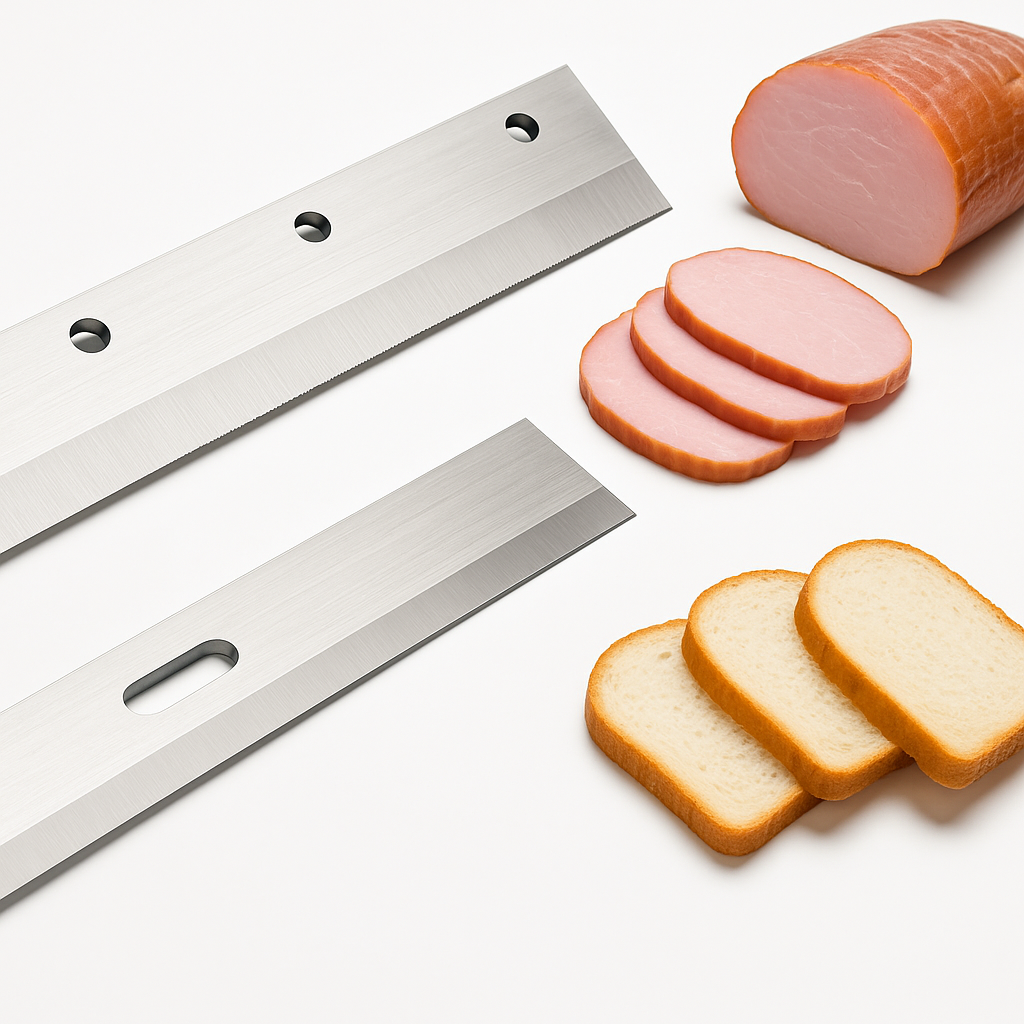

Linear Blades for Slicing and Portioning

Bemar linear blades are designed to guarantee parallel, precise, and uniform cuts on falling-blade or translating-blade systems. Precision grinding and strict control of flatness and cutting angles ensure a clean and consistent finish over time, even during intensive production cycles. Each blade is made of certified food-grade stainless steel, compliant with MOCA regulations and produced according to ISO 9001 standards.

Typical Applications

Linear blades are used in industrial slicing, cutting, and portioning machines operating in the meat, bakery, dairy, and vegetable processing sectors. Thanks to their stability and rigidity, they ensure precise cutting even on hard or fibrous materials, reducing vibrations and mechanical component wear.

Features and Benefits

Bemar linear blades are available with single or double bevel, depending on the required cutting performance, and can be manufactured with holes or slots according to the customer’s drawing for perfect compatibility with your machine. Custom lengths — from inserts to full-width blades — allow integration on systems of any size.

Each blade undergoes precision grinding and flatness testing, ensuring a consistent edge and repeatable cutting quality. High-resistance stainless steels and low-roughness finishes ensure durability, hygiene, and simplified maintenance.

The result is a robust, precise, and long-lasting blade that enhances cutting quality and overall production efficiency.

Hygienic, low-roughness finishes make cleaning easier and reduce the risk of buildup, ensuring optimal conditions for use in food-processing environments. Stainless-steel materials and dedicated anti-corrosion treatments ensure long-term performance, even with frequent washing and intensive production cycles.

The result is an ergonomic, precise, and durable blade capable of combining production efficiency with cutting quality in every stage of processing.

Contact us for more information

Send us your drawing or template: we manufacture your custom linear blade with guaranteed precision, rigidity, and production continuity.